One of the most buzzed-about areas of advanced manufacturing is 3D printing, but not all parts are matches for it, and not all materials are compatible with 3D printers. But let’s say you’ve already determined that the parts you produce are compatible with 3D printers. Now you have to figure out which 3D printing technology is right for you. Depending on factors such as the object you need to print, how fast you need it, the quality required, surface finish, functional parts and implementation costs, one technology might be more suitable than the others.

The number of 3D printing technologies continues to grow, but let’s take a look at three of the main types: stereolithography (SLA), fused deposition modeling (FDM) and selective laser sintering (SLS). Each has advantages and disadvantages.

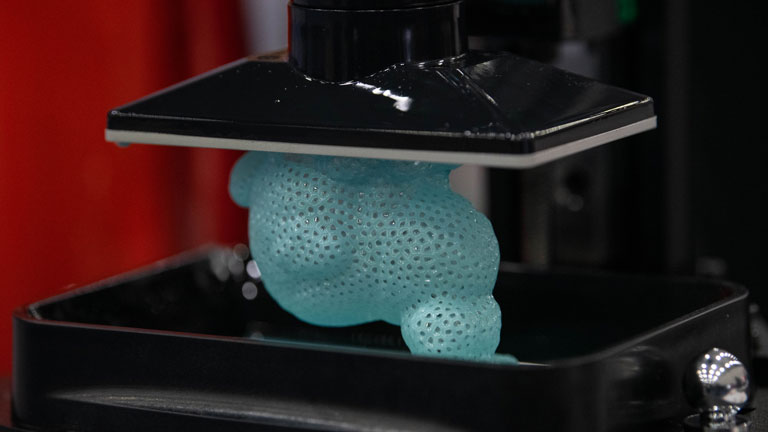

SLA, which may be the first 3D printing concept ever developed, was patented in 1986 by Charles Hull, founder of the 3D Systems Corp. Often used as a stand-in for injection molded plastic parts, SLA focuses ultraviolet light on a vat of liquid photopolymer resin, producing extremely accurate, high-resolution parts in both prototype and production settings. SLA is still being used today, particularly for medical applications and in the dental industry. The downside of SLA is that photopolymer parts don’t have the strength of SLS or FDM 3D-printed parts. The upside is that they can typically achieve much higher resolution and more complex geometries than other 3D printing technologies.1

That brings us to today’s most-used printing technologies, FDM and SLS.2

Compared to other 3D printing technology, FDM is the most affordable. It’s probably also the most popular 3D printing process, due to the number of easy-to-use desktop printers available on the market. With FDM technology, you can print not only functional prototypes, but also concept models and end-use products. The biggest advantage may be that all parts printed with FDM can go into high-performance and engineering-grade thermoplastic.

How does the FDM process work? Material is melted and extruded through a nozzle to 3D print a cross-section of an object, one layer at a time. The bed lowers for each new layer and the process repeats until the object is completed.3

That brings us to SLS, which is very similar to SLA except that SLS substitutes powdered material for liquid resin.4 Significantly more complex than FDM 3D printing technology, the SLS process consists of melting successive layers of powder together to fabricate a solid 3D object, using laser as the power source.5 Unlike SLA and FDM, SLS does not require support structures. Instead, the powder acts as self-supporting material, allowing construction of intricate and complex geometries.6

Used for both rapid prototyping and production, SLS offers many advantages to designers and engineers. Its applications include designs with moving parts, prototypes, consumer products, architectural models, hardware, electronics housing, medical devices and sculptures.7

Explore the latest 3D printing technology at RAPID + TCT, North America’s largest and most important additive manufacturing event. Discover what you’ll experience at RAPID + TCT 2021.

1 “Stereolithography: 3D Printing by Laser Solidifying Liquid Resin,” Sculpteo, https://www.sculpteo.com/en/glossary/stereolithography-definition/.

2 “FDM vs. SLS 3D Printing: What They Mean and When to Use Them,” Lucie Gaget, Sculpteo, July 23, 2019, https://www.sculpteo.com/blog/2019/07/23/fdm-vs-sls-3d-printing-what-they-mean-and-when-to-use-them.

3 “Fused Deposition Modeling (FDM): 3D Printing With Filaments,” Sculpteo, https://www.sculpteo.com/en/glossary/fdm-fused-deposition-modeling-definition/.

4 “How Do We Know Which 3D Printing Technology Is Best?,” Quora, https://www.quora.com/How-do-we-know-which-3D-printing-technology-is-best.

5 “3D Printers and 3D Printing: Technologies, Processes and Techniques,” Sculpteo, https://www.sculpteo.com/en/3d-printing/3d-printing-technologies/.

6 “SLS (Selective Laser Sintering): 3D Printing Powder-Based Process,” Sculpteo, https://www.sculpteo.com/en/glossary/selective-laser-sintering-sls-definition/.

7 “SLS (Selective Laser Sintering): 3D Printing Powder-Based Process,” Sculpteo https://www.sculpteo.com/en/glossary/selective-laser-sintering-sls-definition/.